FTNET respects the privacy of our customers and visitors to our website. We do not translate your Personal Data to third parties, including to third-party advertisers.

All about fuel sensors:

types, operating principle, installation

A fuel sensor is a device that accurately monitors the fuel level in a vehicle's tank. It is an element of the transport GPS monitoring system and controls the following indicators:

- Fuel tank volume

- Diesel/gasoline consumption for a certain period

- Medium fuel consumption for a certain distance

- Refueling and fuel theft

What is a fuel sensor?

Fuel level sensors are used to account for indicators of combustible materials at stationary facilities, for example, in the oil and gas industry (gas stations, etc.), and moving objects - cars, airplanes, ships, road construction and agricultural machinery, etc.

Application

Before choosing a fuel level sensor, you need to take note about the tank size and connection interface.

How to choose a fuel sensor?

Tank parameters: shape, height

Connection interface

This information is extremely important to know before proceeding with the installation of the fuel sensor. The size of the measuring part of the sensor should be slightly higher than the height of the tank: this will allow you to get accurate measurement data even when the tank runs out of fuel. In case the sensor is too long, part of the measuring tube must be cut off so that it touches the bottom.

Basically, fuel sensors with a measuring part from 70 cm to 3 m are on sale. The most used sensor with a measuring part height of 70 cm.

Basically, fuel sensors with a measuring part from 70 cm to 3 m are on sale. The most used sensor with a measuring part height of 70 cm.

If the vehicle already has a GPS/GLONASS tracker, the sensor must be selected based on the interface that the tracker supports.

Types of fuel level sensors

Float-type

Or potentiometric fuel sensor. As a rule, it is standard and is installed by the manufacturer in the fuel tank. The main function is to show how much fuel is left in the tank.

The float and the potentiometer are connected to each other. The float position changes depending on the change in fuel level. Inasmuch as the float is connected to a potentiometer, the result is a change in the resistance of the resistor and the voltage coming out of the sensor. The data from the sensor is sent to the dashboard using a separate wire or an analog signal on older vehicles, using a CAN bus or a digital signal on newer vehicles.

The disadvantage of the float sensor is the inaccuracy of the indicators - error can be 10%-30%.

The disadvantage of the float sensor is the inaccuracy of the indicators - error can be 10%-30%.

How does it work?

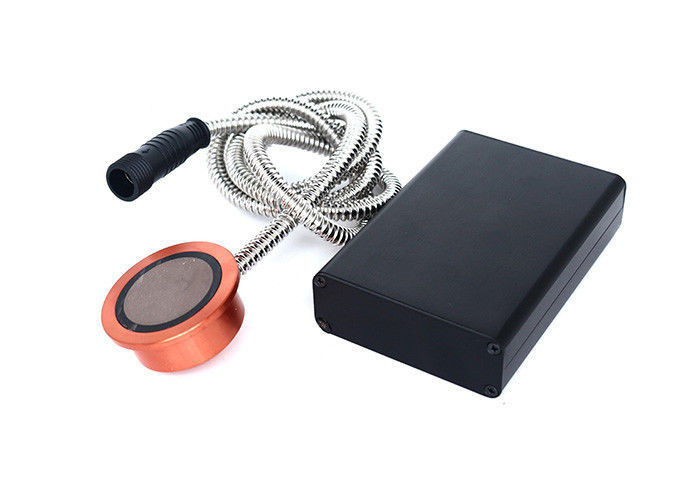

Ultrasonic sensor

This sensor is considered high-precision (1-2% of errors) and it is installed by specialists in integration of satellite monitoring systems.

The ultrasonic emitter has a wire that connects the fuel level sensor and the GPS tracker. The sensor is installed outside in the center of the bottom of the tank, creating an ultrasonic pulse. The impulse enters through the bottom and fuel, reflected and returns to the emitter. The basis for calculating the height of the fuel level in the tank is the time between sending and returning the signal.

Data on measurements and location of the object are transmitted to the monitoring system through the GPS tracker.

Data on measurements and location of the object are transmitted to the monitoring system through the GPS tracker.

How does it work?

Due to installation problems, ultrasonic technology did not show the best results in real life:

.

- Sensor mount

- Partitions

- Rough tank surface

- Foreign objects in the tank

.

The disadvantage of the ultrasonic sensor

Experts recommend using ultrasonic sensors only on gas-powered vehicles.

Capacitive sensor

High-precision device that gives the most accurate readings (1-2% of errors).

How does it work?

Operates on the principle of an electric capacitor, the measuring part consists of two non-contiguous tubes - one inside the other. The tubes are attached to the sensor board and serve as contacts for the measuring capacitor.

Electric current is transferred to the tubes and the fuel serves as a dielectric for the electric capacitor. Since the contact surfaces do not touch each other, the gap between them is filled with fuel when the sensor is immersed into the tank. This means that the fuel level in the tubes and in the tank is the same.

Electric condenser capacity changes as the tubes are filled with fuel. Considering that gasoline has less electrical resistance than air, the charge life of the device will be reduced. Thus, the capacitor is charged faster than the more fuel in the tank.

The time is taken into account in the fuel level sensor board. Calculation of the height of the fuel column in the device and in the tank of the vehicle is based on the received data. Information from the sensor enters to the GPS-tracker and is converted into:

As a result, data from the capacitive sensor is sent to the monitoring system.

Electric condenser capacity changes as the tubes are filled with fuel. Considering that gasoline has less electrical resistance than air, the charge life of the device will be reduced. Thus, the capacitor is charged faster than the more fuel in the tank.

The time is taken into account in the fuel level sensor board. Calculation of the height of the fuel column in the device and in the tank of the vehicle is based on the received data. Information from the sensor enters to the GPS-tracker and is converted into:

- voltage (on analog devices)

- frequency (on frequency devices)

- digital data (on digital devices)

As a result, data from the capacitive sensor is sent to the monitoring system.

Оставьте номер своего контактного телефона, и мы свяжемся с Вами в ближайшее время.

*Мы не передаем информацию о Вас третьим лицам.

In what cases is more than one sensor required for one vehicle?

Sometimes, in order to collect all the fuel consumption data, one fuel sensor is not enough. Let's take a closer look at several similar cases.

- One vehicle, several tanks

- Complicated tank shape

- Elongated tank shape